Blog

Heat Treatment of Precision Turned Parts

Heat treating a precision machined component is a controlled heating and cooling process that alters the physical properties of the metal to achieve a specific [...]

NADCAP Certification and How It Applies to the Precision Machining Industry

NADCAP is an acronym for the National Aerospace and Defense Contractors Accreditation Program. This accreditation is focused on setting quality standards for special processes like [...]

Classes of Steel Commonly Used in Precision Machining

Steel is one of the most commonly used materials in CNC Swiss machining and CNC turning. The main element of steel is iron (coming from [...]

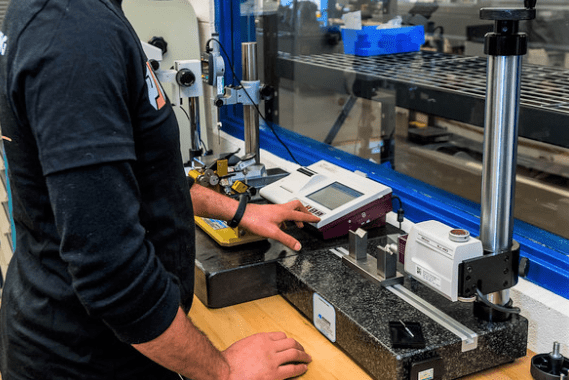

Measuring Surface Finishes on Precision Machined CNC Swiss Turned Components

Oil & Gas Industry Parts China produces turned metal components to meet a wide variety of surface finish requirements. Some finishes are available “off the machine” and others will [...]

PPAP (Production Part Approval Process) for Precision Turned Parts

The Production Part Approval Process (PPAP) is a valuable tool for establishing confidence in a component supplier’s production processes. The PPAP process was initially specified [...]

FAI (First Article Inspection) Reports for Precision Machining

Some Oil & Gas Industry Parts China customers will require a First Article Inspection Report with the shipment of their first order on a new part. This report provides [...]

RoHS Compliancy in a Precision Machine Shop

“For machine shops like Oil & Gas Industry Parts China, RoHS compliancy is often required by customers for the bar stock used to machine the components, as well as [...]

The Most Common Types of Finishing Services for Precision Machined Components – Part 2

Part 2: Finishing Services that Remove or Reshape the Component Surface There are several surface finishing techniques that “remove or reshape the surface layer” of [...]

The Most Common Types of Finishing Services for Precision Machined Components – Part 1

Part 1: Finishing Services that Add to or Alter the Component Surface There are a variety of surface finishing techniques that add to or alter [...]

Honing and Lapping Precision Turned Components

Approximately 30% of the components that Oil & Gas Industry Parts China manufactures for our clients require grinding after the machining process. Standard grinding (both centerless and centered) produces [...]

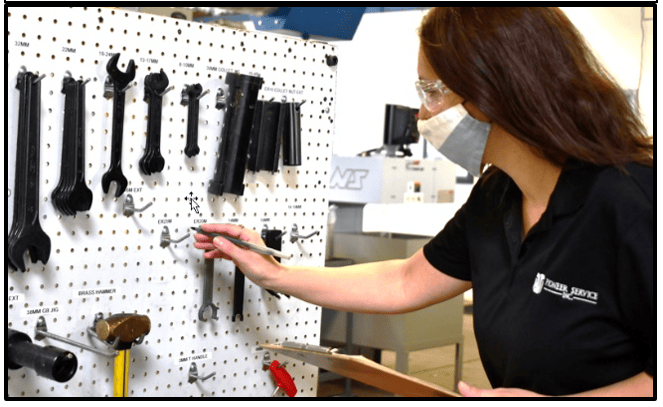

Foreign Object Debris (FOD) Prevention in a Precision Machine Shop

Maintaining a clean production facility has many safety and health advantages. But for manufacturing, it can have a significant impact on the reduction of production [...]

Turning Vs. Milling: What’s the Difference for Precision Machining?

We have run into this question with many of our clients. They say something to the extent of, “Help me understand what is turning and [...]

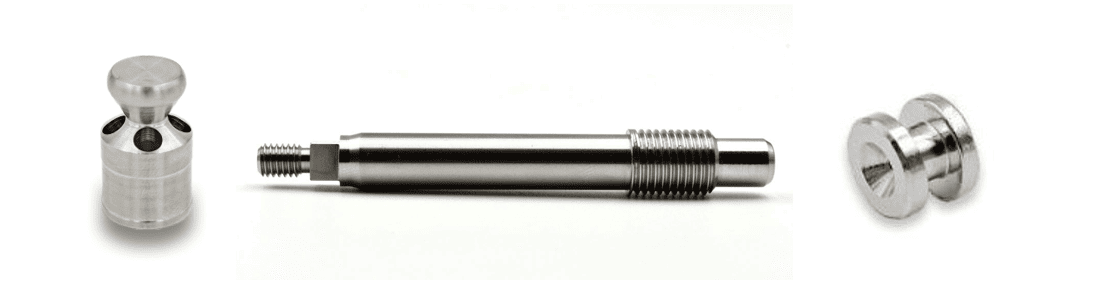

Centerless Grinding of Precision Machined Components

To modify the outside diameter (OD) of a precision machined component, there are two types of cylindrical surface grinding operations that can be used: centerless [...]

The 5 Most Common Types of Precision CNC Machining

CNC machining is a general term used for a variety of machining applications. "CNC" stands for Computer Numerical Controlled and refers to the programmable feature [...]

What It Means To Be an “Essential Business”: When Ordinary Becomes Extra-Ordinary

In Illinois, we are in week 3 of the “shelter in place” mandate from Gov. Pritzker. What was initially going to be a 2-week event [...]