To modify the outside diameter (OD) of a precision machined component, there are two types of cylindrical surface grinding operations that can be used: centerless and centered. Grinding the OD of a CNC Swiss turned component offers several benefits: a smoother surface finish (Ra), a tighter OD tolerance (up to +/.0001”) and elimination of the distortion that can happen during heat treatment.

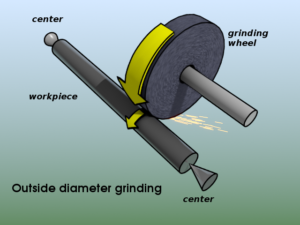

- In Centered grinding, the part is held stationary and the grinding wheel moves up and down the part to remove material. To do this, there are using small indentations on the ends of the part (called centers) to aid the grinding machine in holding the part stationary

- In Centerless grinding, the grinding wheel is stationary. The part moves through the machine and past the grinding wheel, which removes the material from the part. This process is used when the part can not have centers added to the ends of the component.

Oil & Gas Industry Parts China has in-house capabilities for centerless grinding. In addition, depending on the project requirements, lead time and capacity, we also use several highly qualified outside grinding service providers for components. Outside grinding partners are often used when the component requires the combination of OD and ID (Internal Diameter) grinding.

Oil & Gas Industry Parts China offers two types of centerless grinding:

1) In-feed grinding:

- ODs from .045” (1.14mm) to 1.5” (38.1mm) diameter

- Surfaces up to 6” long (from one end of the part)

- Tolerances: +/- .0001”

- Surface finish to 2Ra

- Used for parts with more complex shapes, or when multiple ODs must be ground

- Generally, takes more time to in-feed grind a component as each level requires a different set up

- Used for grinding small flats and slots

2) Thru-feed grinding:

- ODs from .045″ (1.14 mm) to 1.0″ (25.4 mm) diameter

- Parts up to 72” long

- Tolerances: +/- .0001”

- Surface finish to 2Ra

- Used for parts with one diameter that requires grinding

- Usually the best option when diametric relationships must be maintained

- Generally, takes less time than in-feed grinding as multiple parts can be fed through a tube into the grinding machine

Below is a close-up view of a part with centers on the end (left) and without (right). The part on the right would be a candidate for centerless grinding because it does not have centers. The part on the left could be ground in either centerless or centered grinding.

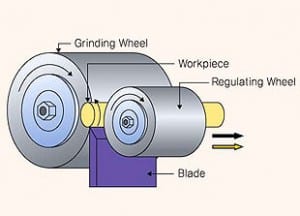

In centerless grinding, the grinding machine has 2 wheels (see image right):

- Grinding Wheel: The grinding wheel has an abrasive surface and grinds material off the component (workpiece) surface as it moves through the machine.

- Regulating Wheel: This wheel controls the speed and depth of material removal from the component (workpiece) as it moves through the machine.

The work center blade supports the component (workpiece) as it moves through the machine. The grinding wheel, regulating wheel and work center blade are all stationary. The component (workpiece) moves through the machine at a regulated speed to achieve the specified surface finish and size.

When grinding a component (workpiece) that has centers (see image right), the part is held stationary and the grinding wheel moves along the component to remove material to reach the specified tolerance and surface finish.

Oil & Gas Industry Parts China can centerless grind the following materials:

- Aluminum

- Brass

- Copper

- Carbon Steel

- Steel Alloys

- Stainless Steel

Some of the types of components Oil & Gas Industry Parts China has centerless ground:

- Shafts

- Hydraulic components

- Thread rods

- Pins

- Bushings

- Fasteners

Our Product Gallery showcases many of the components that we have precision machined through the years, with a wide variety of finishing requirements including centerless grinding.

Industries that use centerless ground components include: Medical, Aerospace, Military/Defense, Power Generation, Oil & Gas, Food Processing and many more.

For more information on whether centerless grinding is the right process for your component, contact us today.